RAPID PROTOTYPING TOOLING SERVICES

RAPID PROTOTYPING TOOLING SERVICES

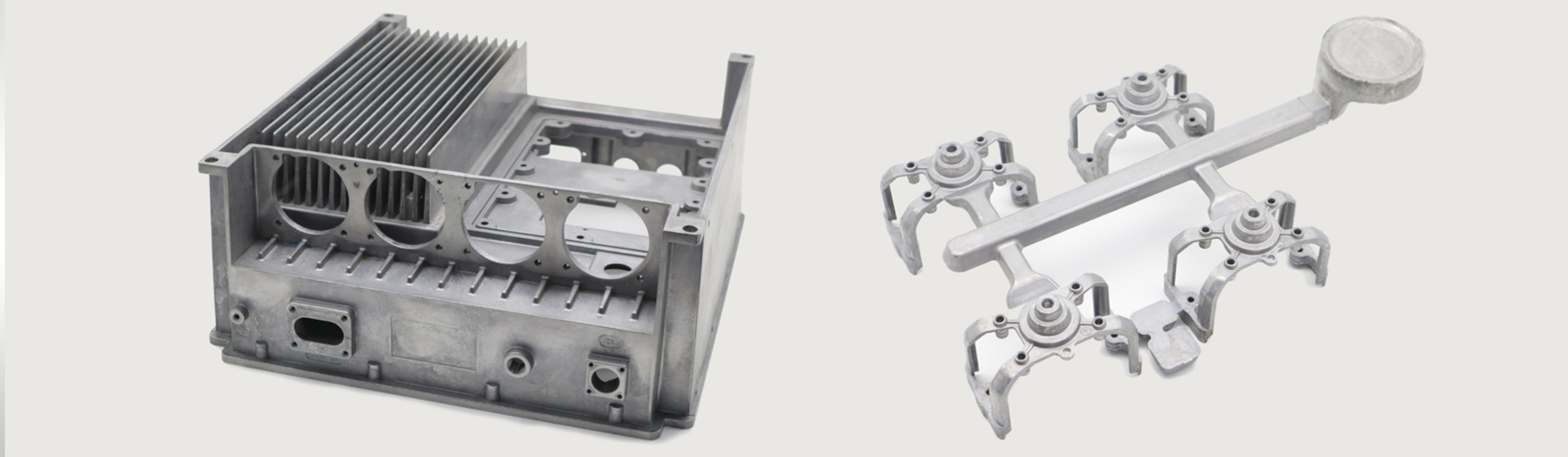

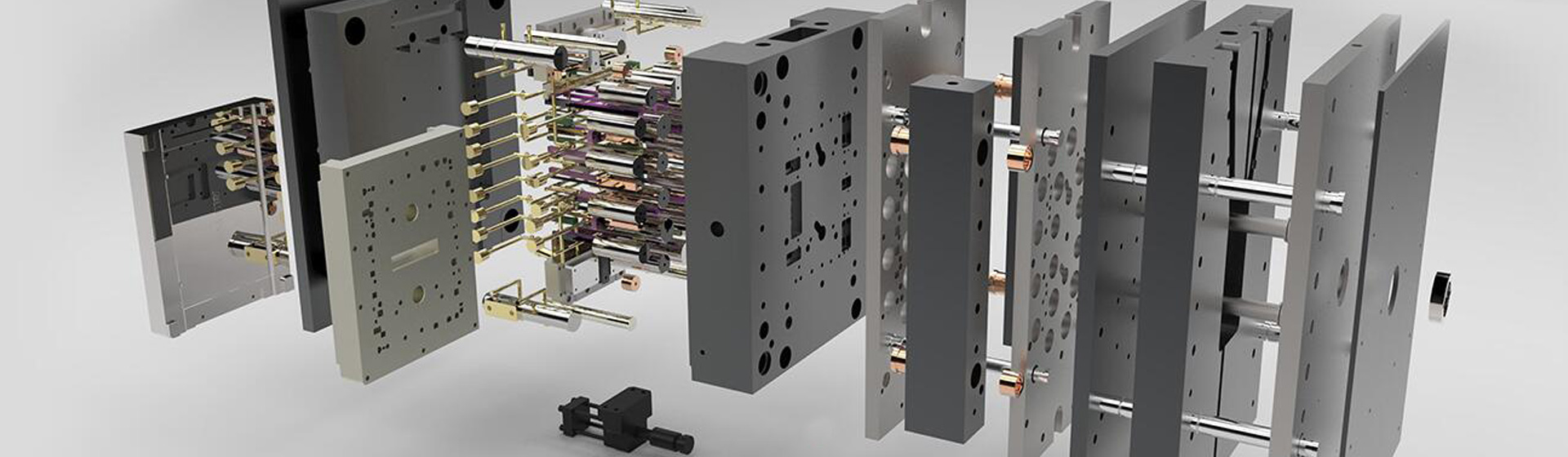

Low volume prototype is the best way to save time and cost for testing form and fit as well as preliminary market test, but anyhow it cannot match the final finish and function effect of the injection molded plastic parts. When your production tooling wonĄŻt be ready for months, rapid injection molding (also known as prototype molding or soft tooling) then is a great option for you to receive parts quickly with less cost.

GTS invests in an independent injection molding factory which can use various materials and techniques to create bridge tooling for prototype testing and pre-production evaluation. We deliver injection molded parts on your schedule to support your entire testing, and help troubleshoot possible process issues in full production.

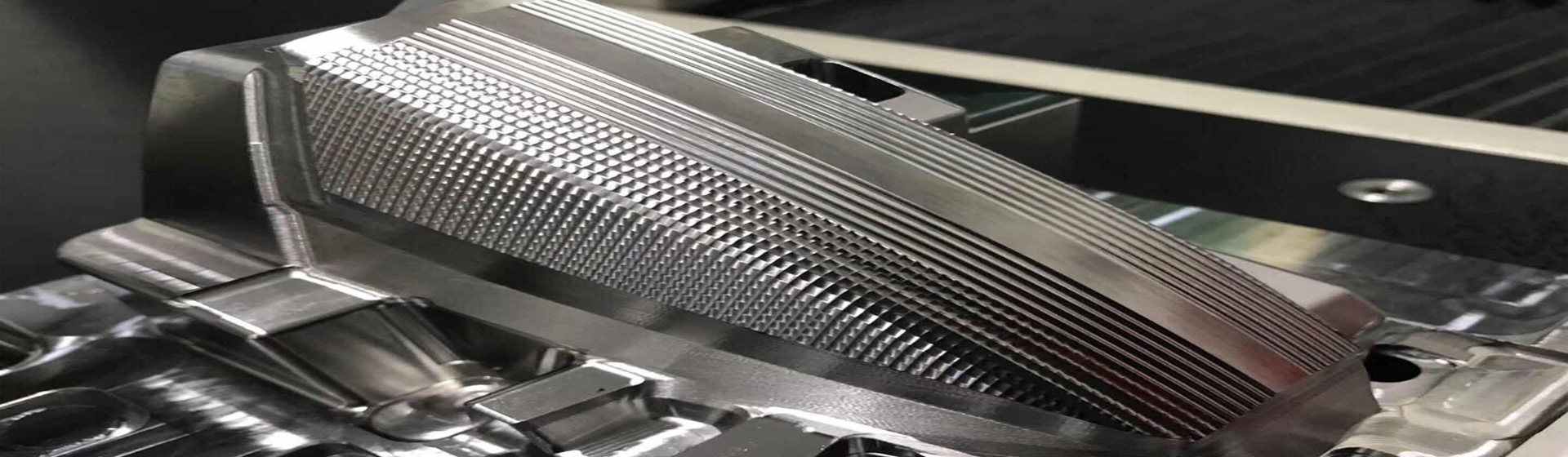

At GTS, we specialize in rapid molds of both aluminum and steel and low-volume plastic molding. With technical experience in injection molding, rapid tooling, CNC machining, EDM processing, and specialty finishing, we ensure your parts meet and exceed your highest expectations.