Ready for a more cost- and time-efficient way to manufacture parts? Our high mold manufacturing knowledge and strong engineering team help you reduce design risks and limit overall production costs along every step of the product cycle. At GTS, our injection molding and die-casting services are designed for both low-volume and mass production of end-use parts, production tooling for high-volume production, mass customization of product lines. Our plastic injection molding and die-casting processes produce custom prototypes and end-use production parts in 15 days or less.

How does plastic injection molding work?

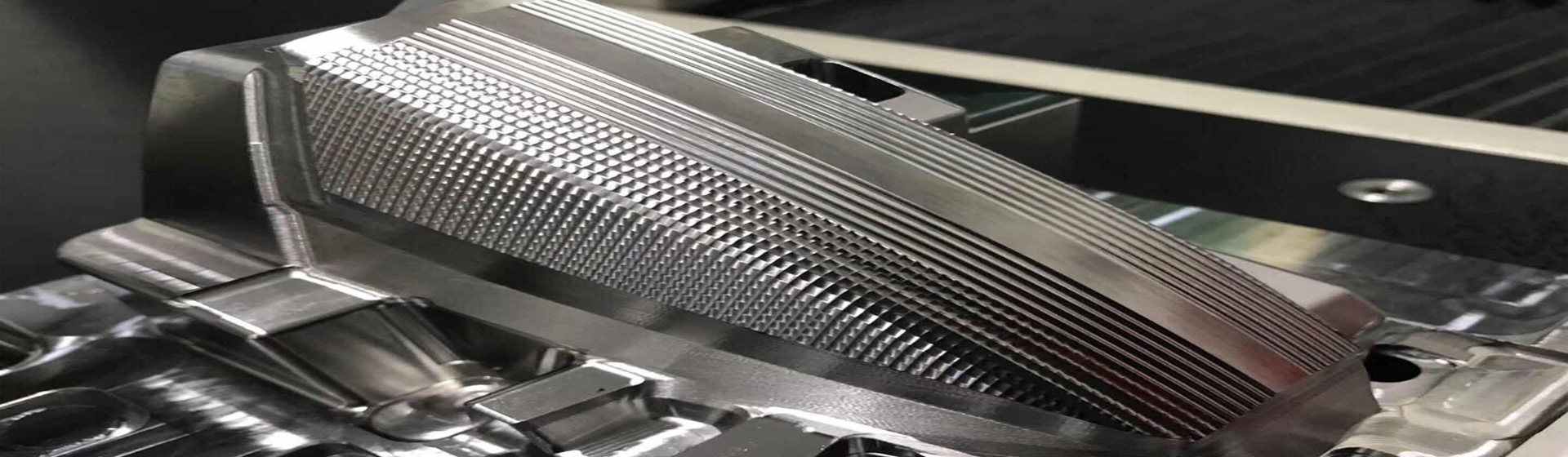

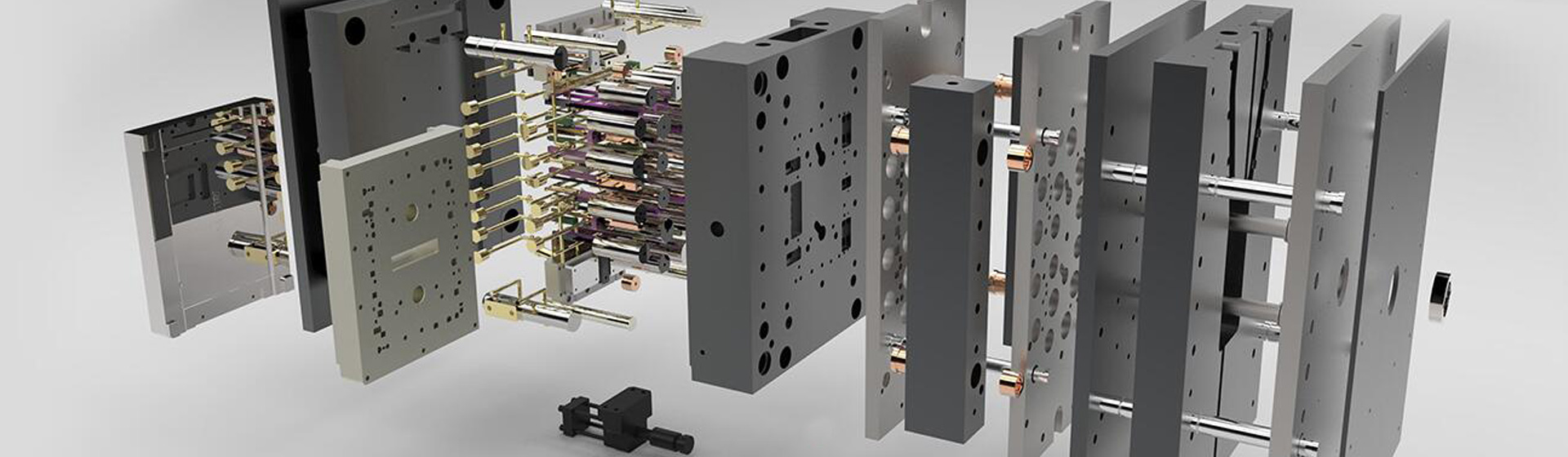

The thermoplastic injection molding process at Work technology is a standard process involving an mold with heating or cooling lines running through it to make the shorter cycle time and improve the surface quality. It allows our molders to monitor fill pressure, cosmetic concerns, and the basic quality of the parts. Resin pellets are loaded into a barrel where they will eventually be melted, compressed, and injected into the mold's runner system. Hot resin is shot into the mold cavity through the gates and the part is molded. Ejector pins facilitate removal of the part from the mold where it falls into a loading bin. When the run is complete, parts (or the initial sample run) are boxed and shipped shortly thereafter.

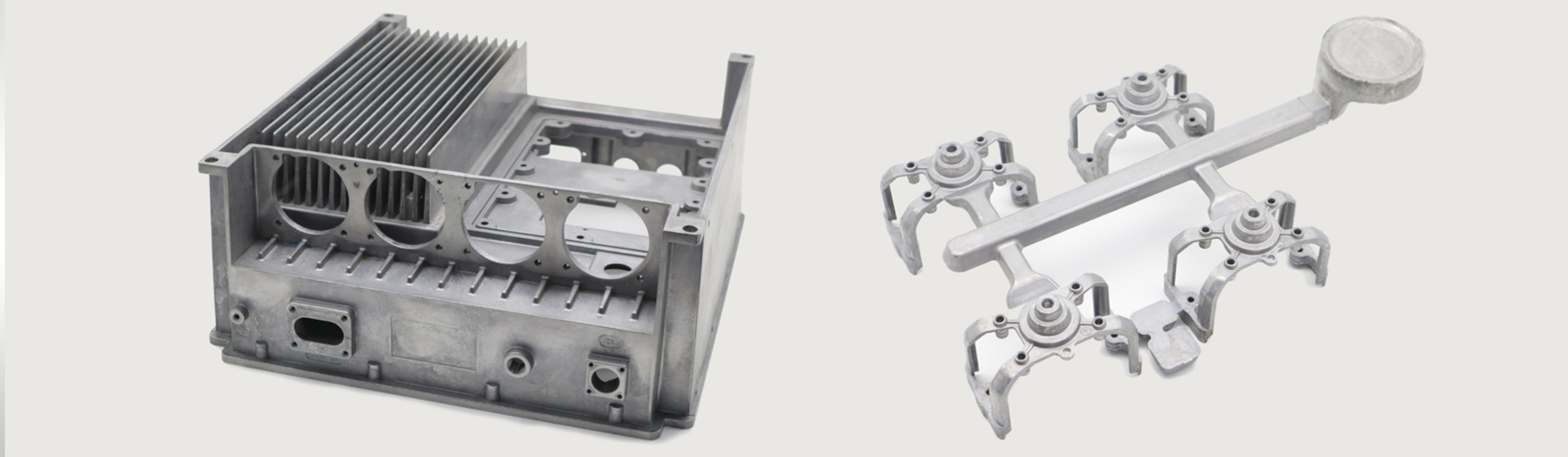

How does die-casting molding work?

Die casting at Work Technology is a standard manufacturing process that can produce geometrically complex metal parts through the use of reusable molds, called dies. The die casting process involves the use of a furnace, metal, die casting machine, and die. The metal, typically a non-ferrous alloy such as aluminum or zinc, is melted in the furnace and then injected into the dies in the die casting machine. There are two main types of die casting machines - hot chamber machines (used for alloys with low melting temperatures, such as zinc) and cold chamber machines (used for alloys with high melting temperatures, such as aluminum). The differences between these machines will be detailed in the sections on equipment and tooling. However, in both machines, after the molten metal is injected into the dies, it rapidly cools and solidifies into the final part, called the casting. The steps in this process are described in greater detail in the below flash.