Looking for a reliable, quick-turn supplier of machined plastic and metal components? With hundreds of mills and lathes, our unmatched in-house capacity ensures your parts are shipped on-time, every single time. At GTS, our CNC machining service is designed for both rapid prototyping and low-volume production of end-use components.

Which Machining Process Should I Use?

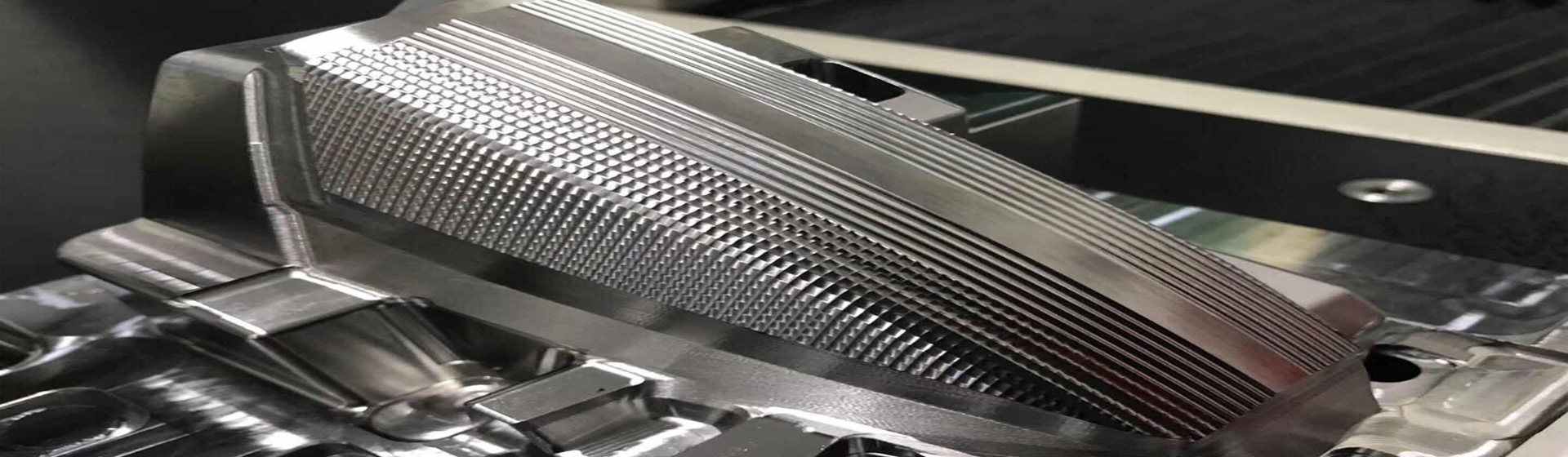

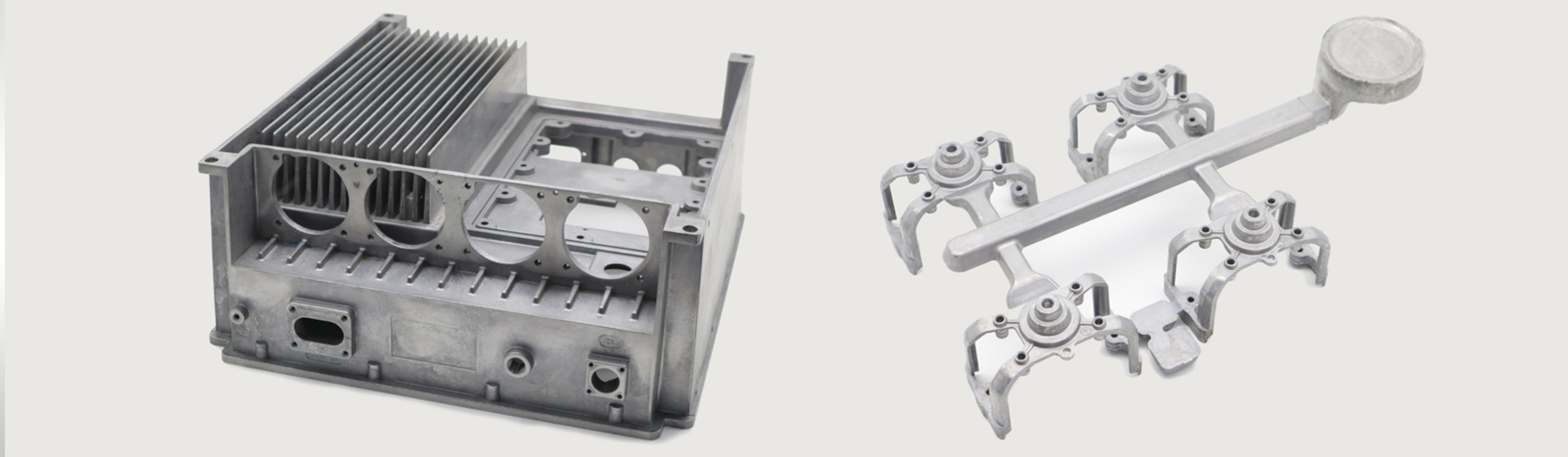

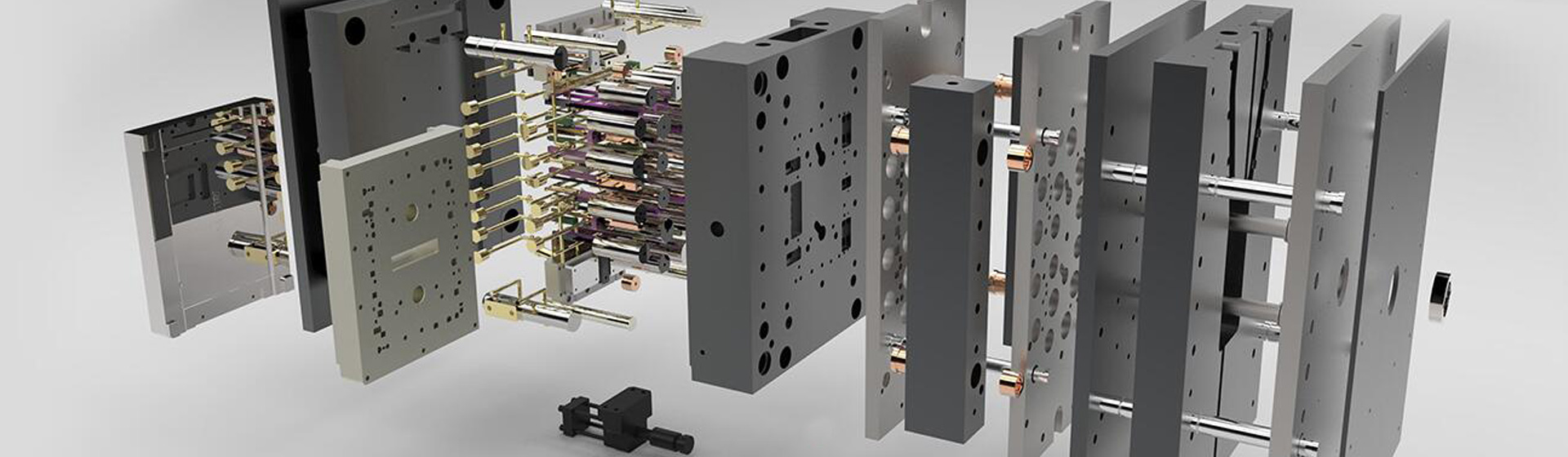

CNC Milling

Our CNC milling process produces custom prototypes and end-use production parts in as fast as 1 day. We use 3-axis milling and 5-axis indexed milling processes to manufacture parts from more than 30 engineering-grade plastics and metals.

How Does CNC Milling Work?

We have multiple toolsets based on efficient cutters for a particular plastic or metal material. The machine then rapidly mills parts out of the block in a subtractive manufacturing process that uses either 3- or 5-axis milling. Machined plastic parts are left as-milled, which typically means they show visible tool marks. Some metal parts allow more finishing choices. When the run is complete and your required surface finish is applied, parts are boxed and shipped shortly thereafter.

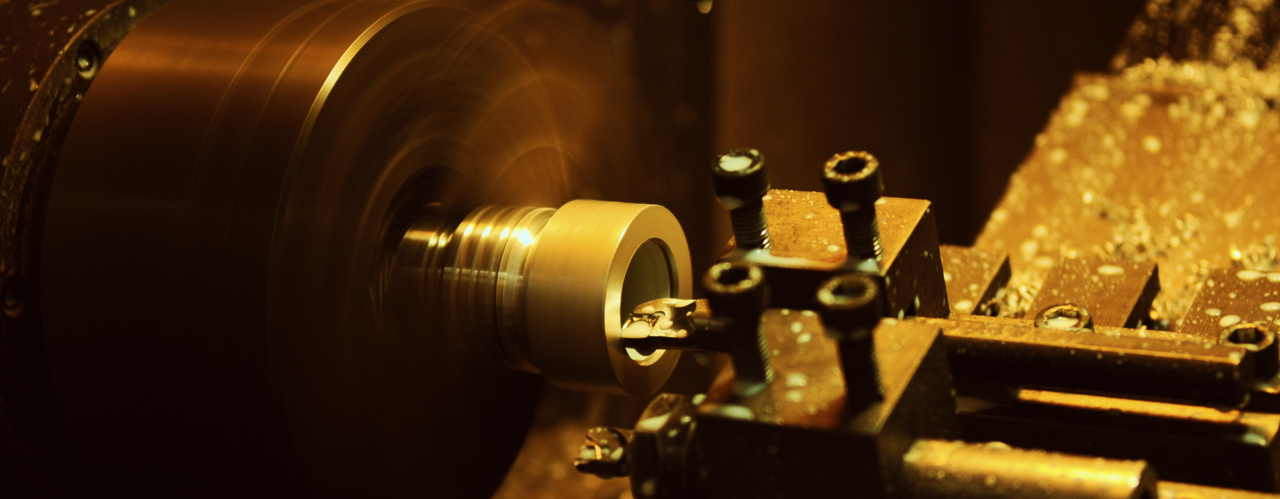

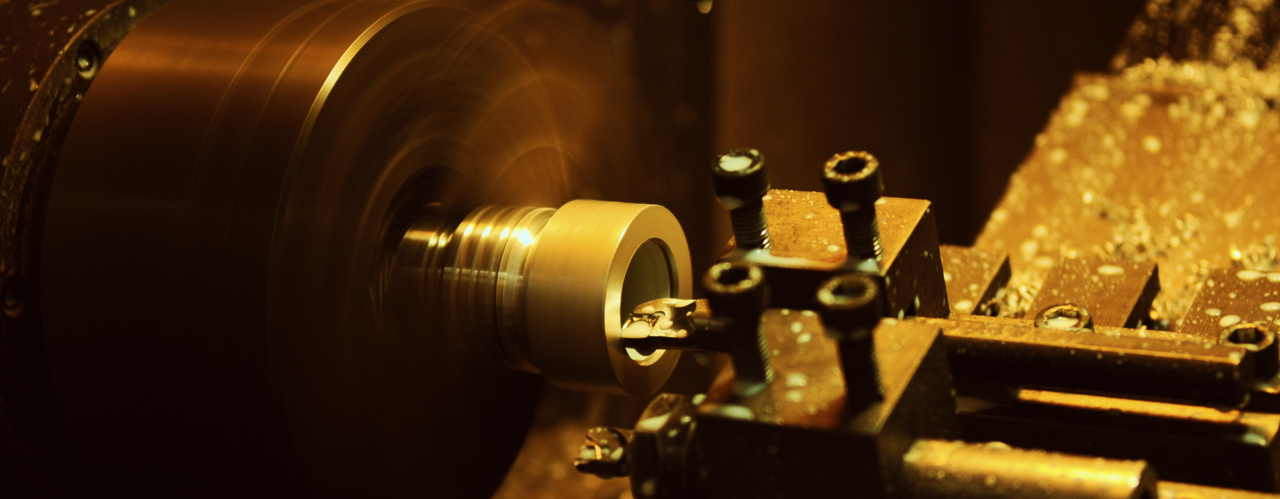

CNC Turning

Our CNC turning process produces custom prototypes and end-use production parts in as fast as 1 day. We use a CNC lathe with live tooling so features like axial and radial holes, flats, grooves, and slots can be machined.

How Does CNC Turning Work£¿

During the CNC turning process, a metal rod is rotated while a cutting tool is held against the stock to remove material and create final parts. The lathe rapidly machines your parts in a subtractive turning process with additional live tooling. Outside diameter (OD) and inside diameter (ID) threading is also available.Turned parts can then be left as-machined, with visible tool marks, or bead blasted. When the run is complete, parts are inspected, boxed and shipped shortly thereafter.